Services

The advantage of these valves is that they have poor choking properties, which can hasten the deterioration of a ball valve's seat. They offer servicing without leaks. They have several uses in the areas of water supply, sewage treatment, fire prevention, and other things as well.

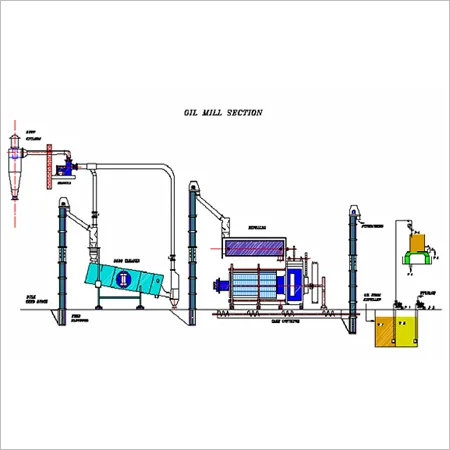

The provided oil expellers are uniquely created to guarantee contemporary oil extraction and maximal oil extraction from all types of oil seed. For pressing the majority of oil seeds, they are intended. These are quite effective in extracting the oil and producing the output.

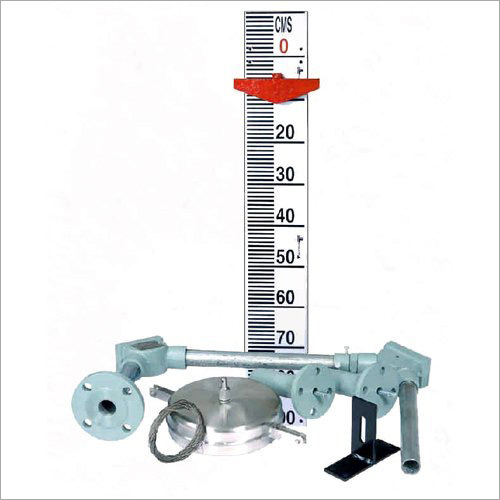

Utilizing the Level Switches that are available, liquid interfaces and levels may be detected. By turning on and off a load, these switches may be used as either control switches or alarm devices. They are employed in the detection and measurement of various materials.

The flow rate of a liquid or a gas is measured using these devices. This meter has a tapered tube that passes through a floating internal element. Rotameters are occasionally referred to as gravity flow meters, mechanical flow meters, or variable area flow meters.

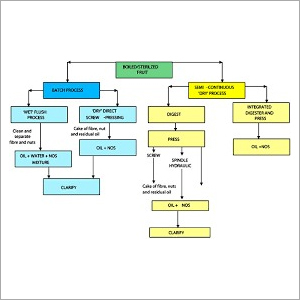

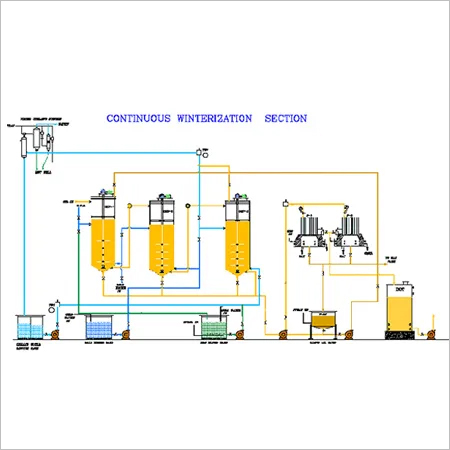

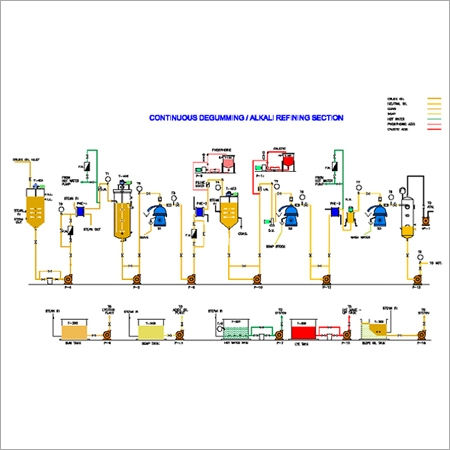

Oleo chemicals are used in many different sectors as both

primary materials and supplementary compounds. These can be used in place of

petrochemicals, or goods made from petroleum. These substances are becoming

more well-liked as a result of its many environmental advantages.

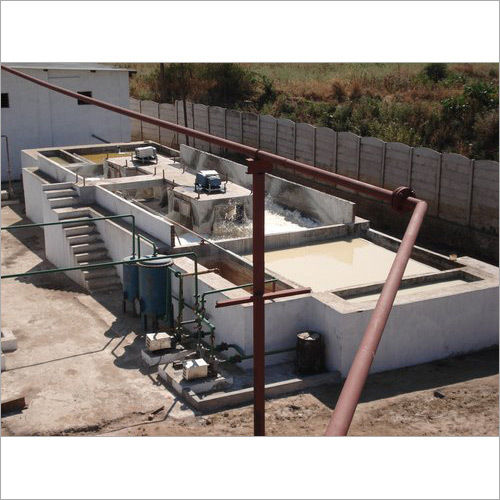

The removal of significant quantities of organic compounds, debris,

dirt, grit, pollution, poisonous, non-toxic materials, and polymers, among

other things, from industrial wastewater is done using effluent treatment plants. Evaporation, drying, and other auxiliary

procedures are employed by the ETP plants.

Our company is dedicated to producing a superior selection of FRP Cooling Towers. We make sure that these items should be of excellent quality and would be able to satisfy specific requirements of clients with ease thanks to fantastic technical assistance and outstanding research and development services.