Batch Oil Refinery Plant

100000.00 - 200000.00 INR/Unit

Product Details:

- Material Stainless Steel

- Computerized Yes

- Voltage 380

- Power 30 Watt (w)

- Weight (kg) 1500 Kilograms (kg)

- Dimension (L*W*H) 18MX12MX18

- Color Yellow

- Click to View more

X

Batch Oil Refinery Plant Price And Quantity

- 100000.00 - 200000.00 INR/Unit

- 1 Unit

Batch Oil Refinery Plant Product Specifications

- 380

- Yellow

- 18MX12MX18

- Yes

- 1500 Kilograms (kg)

- Stainless Steel

- 30 Watt (w)

- Yes

Batch Oil Refinery Plant Trade Information

- Cash Advance (CA)

- 10 Unit Per Week

- 7 Days

- All India

Product Description

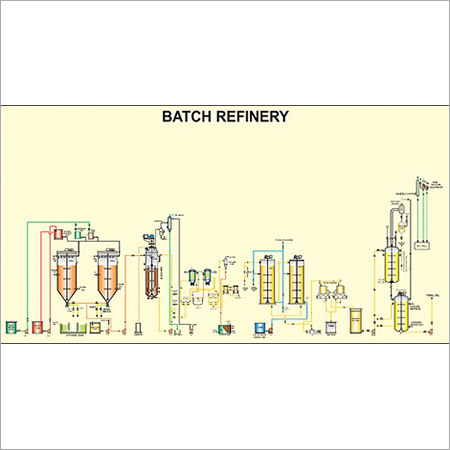

Spectec Techno Projects Private Limited offers Continuous Refinery Plants with latest technologies, both manual & PLC controlled plantsOil Refning is the process of removing unwanted moisture, impurities, free fatty acid, gums, waxes, color & odors.

The oil can be processed by two different methods:

- Batch Refinery

- Continuous Refinery

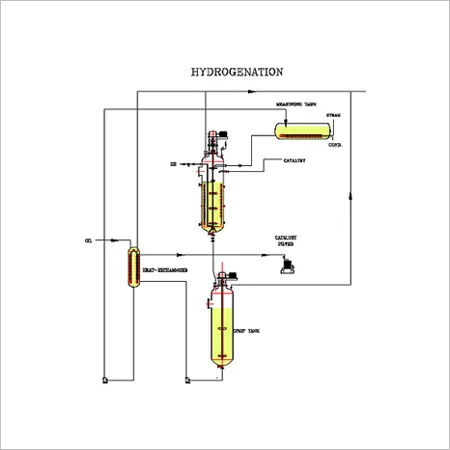

BATCH REFINERY

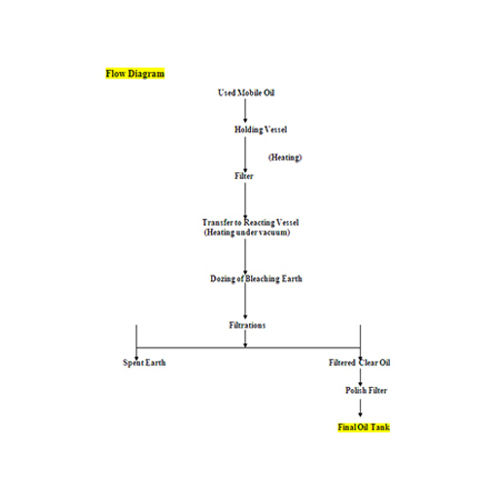

In batch refining process a measured batch of crude oil is processed in sequence of nutralizing, bleaching, dewaxing & deodorizing.

Crude oil obtained from expellers, solvent extraction plant contains foreign impurities such as gums, mucilage and unfiltered proteinous matter from the seed. It also contains gums which make it unfit for edible purpose.

Batch refining consists of following sections.

- Bleaching

- Deodorizing

- Dewaxing

- Neutralizing

The first stage of refining is to separate these gums & foreign impurities with chemicals and hot water treatment called degumming process. Thereafter, the degummed oil is further processed in bleaching section under vacuum and treated with bleaching earth and carbon for reduction of colour pigments. Next, it deodorized under high vacuum. The edible oil obtained from batch refinery is of good quality meeting all requirements of international standards.

Enter Buying Requirement Details