Hydrogenation Plants

9000000-50000000 INR/Unit

Product Details:

- Material Stainless Steel

- Capacity 5 To 500 Ton/day

- Purity(%) 98%

- Weight (kg) 1000-2000 Kilograms (kg)

- Voltage 380 Volt (v)

- Dimension (L*W*H) 2000x1400 Millimeter (mm)

- Warranty Yes

- Click to View more

X

Hydrogenation Plants Price And Quantity

- 9000000.00 - 50000000.00 INR/Unit

- 1 Unit

- 9000000-50000000 INR/Unit

Hydrogenation Plants Product Specifications

- 1000-2000 Kilograms (kg)

- 380 Volt (v)

- Stainless Steel

- 98%

- 2000x1400 Millimeter (mm)

- Yes

- 5 To 500 Ton/day

Hydrogenation Plants Trade Information

- 10 Unit Per Week

- 7 Days

- Western Europe Middle East Central America Eastern Europe South America Australia Asia North America Africa

- All India

Product Description

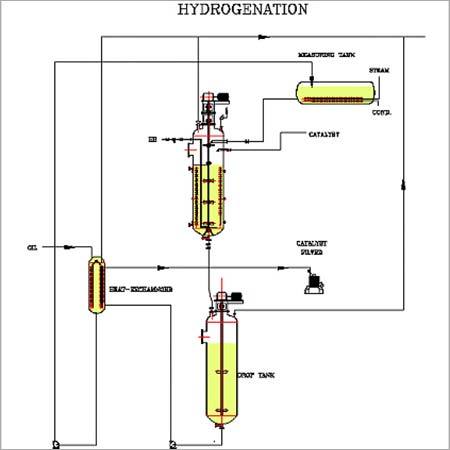

All the solid ingredients packed in bags for feed production would be received in plant by road. Their materials will be stored in store godown. According to the requirement these materials will be dumped manually in dumping hopper and conveyed to the pre-cleaner through the mechanical conveyor system.Hydrogen Design and Control

The use of hydrogen requires safeguards against creating an explosive mix of hydrogen and air. Typically, a hydrogenation vessel undergoes a pressure test followed by various nitrogen purges before hydrogen is introduced. Similarly, at the end of the reaction process, the vessel is purged with nitrogen in order to leave it in a safe condition. Normally, a hardwired safety system confirms the pressure test and nitrogen purge phases before allowing the hydrogen line to be opened. The hydrogenation requires high pressures to be maintained in the reaction vessel giving problems over maintaining seals around agitators which in some cases require additional seal integrity checks or upgrades to incorporate magnetic coupling systems.

The hydrogenation also tends to be a highly exothermic reaction, resulting in demanding temperature control requirements.

A control system must therefore provides flexibility in the way in which accurate and repeatable control of the hydrogenation environment is achieved and will include the following features:

Sequential control for vessel pressure testing, purging and hydrogen addition.

Local operator display with clear graphics and controlled access to parameters.

Secure collection of on-line data from the hydrogenation process for analysis and evidence.

Precise loop control for temperature and pressure.

Enter Buying Requirement Details